In the realm of refrigeration, mastering the defrost cycle of your cold room isn't just a maintenance task—it's an essential skill that can significantly impact your system's efficiency, longevity, and energy consumption. With each cold room boasting a unique set of parameters influenced by brand, model, and operational demands, navigating through these settings to optimize your defrost cycle can seem like a daunting endeavor. But fear not, for we are here to demystify this process. Armed with expert knowledge and industry insights, we're turning complex adjustments into straightforward strategies. Let's dive into the world of cold room controllers and unlock the secrets to an efficient defrost cycle.

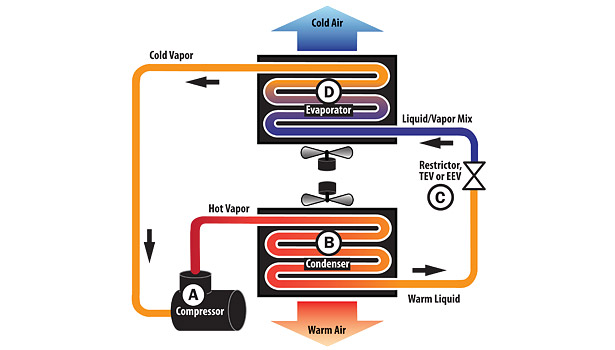

Photo credited by: https://www.achrnews.com/articles/117734-frost-and-defrost-how-it-happens-and-why-it-is-needed-a-white-paper

Understanding the Core Parameters

Defrost Intervals:

Think of defrost intervals as the heartbeat of your cold room's defrost cycle. The timing of these intervals is pivotal, generally ranging between 4 to 8 hours, with 6 hours marking the industry standard. However, this isn't a one-size-fits-all scenario. For cold rooms serving as long-term storage with infrequent door openings, stretching intervals to 8 hours can cut down energy use. Conversely, high traffic systems demand shorter intervals to prevent ice buildup beyond the system's defrosting capacity.

Defrost Duration:

Duration dictates how long the defrost cycle runs. While a ballpark figure is between 20 to 40 minutes, the exact timing hinges on your defrost method. Air current systems need a precise adjustment within this range, whereas hot gas and electric systems can lean towards the upper limit. The trick lies in stopping the cycle at the right moment, often dictated by other system parameters, to ensure efficiency without compromise.

Defrost Termination Temperature:

This parameter is the defrost cycle's safety net, ensuring no ice remains on the evaporator coil. While ice melts at 0°C, setting your termination temperature a bit higher (between 6 to 8°C) guarantees a thorough defrost. In cases where the evaporator fins are uneven, bumping this up to 20°C might be necessary to ensure all ice melts, showcasing the need for a nuanced approach to this setting.

Draining Time:

Post-defrost, it's crucial to allow condensation water to exit the system efficiently, typically over a span of 2 to 4 minutes. This interval is vital for the system to manage heat tension, ultimately extending the life of evaporator components.

Fan Start/Stop Temperature:

This often-overlooked parameter plays a significant role during and after defrost, particularly in electric and hot gas systems. Setting the restart temperature for evaporator fans below zero (between -5 to -10°C) in freezer systems prevents condensation water from splashing onto surfaces, ensuring it freezes before fan activation. This step is crucial for maintaining system integrity and preventing ice buildup in areas outside the heaters' range.

Beyond the Basics

While the parameters outlined above are pivotal, they only scratch the surface of optimizing your cold room's defrost cycle. Advanced settings, specific to your system's make and model, offer additional avenues to enhance efficiency and reduce energy consumption. Engaging with these settings requires a deep understanding of your system's operational dynamics and environmental conditions.

The Role of Expertise

Navigating the complexities of cold room defrost cycles demands more than a cursory understanding of the system. It requires expertise, experience, and a willingness to delve into the specifics of each system's needs. As industry professionals, our role transcends providing services; it's about empowering you with knowledge and insights to make informed decisions about your refrigeration systems. By sharing our expertise, we aim to elevate the industry standard, ensuring that efficiency and sustainability are within reach for every operator.

Conclusion

Mastering the defrost cycle of your cold room is a journey that combines technical know-how with practical experience. By understanding and adjusting the critical parameters of your cold room controllers, you can significantly enhance your system's efficiency, reduce energy consumption, and extend its lifespan. Remember, each cold room is unique, and finding the optimal settings requires patience, experimentation, and a deep dive into the specifics of your system. As your partners in refrigeration excellence, we're here to guide you through every step of this journey, ensuring your cold room operates at its peak potential.